|

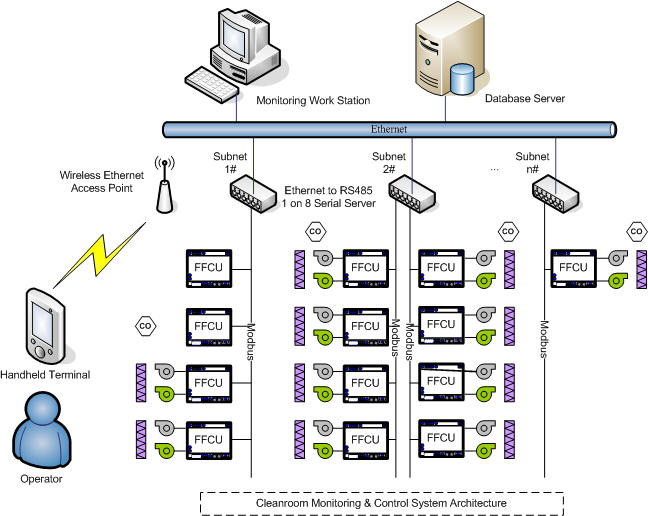

FFU Control & Monitoring System

This system has been

designed to monitoring and control fan filter units

(FFUs) to maintain clean-room conditions for

semiconductor production lines or medical operations to

achieve safety, reproducibility, easy to operate and

energy efficiency. This system can be also used in

monitoring environmental varieties like temperature and

humidity, or working status of critical equipments, and

managing or optimizing energy usages together with other

controllers from Shanghai TiGon Intelligence Technology

or third parties.

Single-Phase AC Motor Controller

|

Model:

FCU102 |

☺ |

Modbus RTU |

☺ |

50/60Hz |

☺ |

95-250VAC |

☺ |

Single-phase |

Features

-

Controls two Fan filter units

simultaneously and individually for 24 hours

-

Linear control wind speed,

from 30%* to 100%

-

Modbus RTU network compliant

-

Local and Remote

operation options

-

Manual or Automation modes

available

-

Scheduler/Calendar supported with set

speeds for weekdays or off days. Real time clock embedded

and synchronized

-

Soft-Start supported with

deterministic 0-26s delay considering power load impacts

-

Closed loop control, accepts

FFU currents feedbacks

-

Fault safety supported with LEDs indicate idle load,

overload or communication errors, alarm outputs with dry

contact and sound options

-

Authentification

mechism option available to prevent unwanted changes from

occuring

-

Non-volatile

memory keeps setting even

power goes out, re-starts or network connection is

broken

-

50Hz or 60Hz compatible

-

Low power consumption,

transformer isolated

-

Low harmonics

-

Compact design, L97.6mm x

W106mm x H81.1mm

-

DIN rail mounting or ceil

mounting

-

Configurable standard firmware

supplied pre-loaded, support for custom program development

available

*Note: Recommended range may vary for

different motor models

Overview

Fan Filter Control Unit

(FCU102) is a compact,

TRIAC based fan & motor control designed for applications

like clean room pressurization, ceiling fans, exhaust

ventilators, pumps, duct fans & blowers. Also

it provides a cost effective way to have a intelligent and

networkable system.

Benefits of using FCU102 include acoustical noise reduction,

environmental (pressure or flow) regulation, greater system

reliability, increased fan life, improved safety and energy

savings.

Finanical Benefit

For operation

owners of minienvironments within large cleanrooms or small

installations (100 FFUs or less) which dominate the market

need (over 90% of all installations),

whatever if they want centralized control at a reasonable

cost, or require frequent adjustment of flow rates, or just

for energy conservation sakes, it would be a wise choice to

consider FCU102. The savings in set up time, callibration

efforts and electricity consumption will offset most of cost

of this system over manual control with signficantly quieter

performance.

Usually the investment would be returned in only 3 to 6

months!

Ease of Installation/Balancing

For small AC systems, a

customer can save 50% of the installation and balancing time

to hook up. At rates of $75 to $100 per hour for

installation and balancing cost, the savings can be

significant.

Electricity Saving & Set-Back

Results

Consider a cost analysis of an

AC system using 2 x 4 ft. FFUs typically running 250 watts

at full speed. A small cleanroom was operated typically 10

hours per day, 5 days per week. A setback to 110 watts (500

RPM from 1100 RPM) was requested. Calculating the savings at

a cost of $0.22 per kwh, system savings exceed $150/year.

Without any other savings, the payback for controller was

approximately ONE month. A good

rule of thumb is for every 50 watts of power one can

set-back and save, one can reduce electric consumption by

more than $50.00 per year ($1/year/watt saved upon

set-back).

When one includes lower

installation and balancing costs, ease of reducing full

speed flow to optimize the cleanroom application, and the

cost saving on the filter media by extending its useful

life, it is estimated that a payback of less than 3 months

is realistic. Along with the lower fan noise and the

flexibility to adjust and reconfigure cleanroom space, the

system is now very cost effective.

System

System components include:

-

Ethernet to RS485

Serial

Server (Model: 32104 / 32108)

- Supports up to 30 individual FFCUs (60 units FFUs) each

port, and total 120/240 individual FFCUs (240/480 units

FFUs) for a subnet with 32104/32108. Only one Serial Server

would be good for typical

. For large installations, applying with 32 units 32108

Serial Servers, the total FFU capability would be 32*8*30*2=15,360

units

-

Handheld Terminal

(Model: HC7001) - Provides great conveniences to operators,

maintain technicans and managements monior or configure

system or individual FFU anytime or anywhere. Mobile

applications, diverse platforms available - iPhone 4S,

iPad2, Blackberry, HP PDA, etc.

Contact us if

you need it on your new mobile phone...

System or Software highlights:

-

Low cost, low effort for

commissioning or maintain

-

Remote maintenance and

configuration via Ethernet even Internet connection

-

Convenient time scheduler for

automated FFU control (speed-up or speed-down of single FFUs

or groups)

-

Floor-plan layout and local

control templates available and easy to use

-

Registration of each FFU run

time for preventive filter maintenance

-

Event logging (status- and

change logfile) for post moterm analysis

-

Easy to be integrated with DC

motor control systems

|

|

|

|

| a) Cleanroom

Overview |

b) Individual

FFU Control |

c) Zone/Group

Control |

d) FFU Alarm

Monitoring |

Figure 1. FFU

Control System Human Machine Interface Examples

Technical Competitive Advantages

|

Competitor 1

(China) |

Competitor 2

(US) |

Our Product |

|

FFU to be

controlled |

1:1 or 1:2 |

1:1 |

1:2 |

|

Speed Control

Range |

Narrow |

Wide |

Wide |

|

Mannual Control

Onsite |

|

Additional

console needed |

|

|

Schedule Control |

|

|

|

|

Code Access

Control |

|

|

|

|

Communication

Protocol |

Self-defined |

Modbus RTU |

Modbus RTU |

|

Address

Capability |

256 |

127 |

240 |

|

50/60Hz

Compatible |

|

|

|

|

Soft Start |

|

Partially |

|

|

Harmonic

Distortion |

Unknown |

Unknown |

Low |

|

Data Keeping |

|

Partially |

|

|

Backup Battery |

|

|

|

|

Sound Alarm |

|

|

|

|

Alarm Output |

|

|

|

|

Multi

Installation |

|

|

|

|

Certification |

|

CE |

CE |

Specification

|

Network |

|

Protocol |

Modbus

RTU |

|

Maximum

Nodes Per Channel |

30 (-40

to + 85DegC) |

|

Network

Wiring |

22 to

16AWG Twisted Pair |

|

Electric |

|

Supply

Voltage |

95-250VAC,

Automatically detected |

|

Power

Frequency |

47-64Hz,

Automatically detected |

|

Power

Consumption |

<4W |

|

Environmental |

|

Operating Temperature |

-10 to

+70 DegC |

|

Non-operating Temperature |

-40 to

+85 DegC |

|

Operating Humidity |

25 - 90%

RH @ 50 DegC, non-condensing |

|

Non-operating Humidity |

95% RH @

50 DegC, non-condensing |

|

Physical |

|

Dimensions |

L97.6mm

x W106mm x H81.1mm |

|

Weight |

approx.

200g |

|

Protection |

IP20 |

|

Installation |

DIN-rail

Mounting, Ceiling Mounting |

|

Others |

|

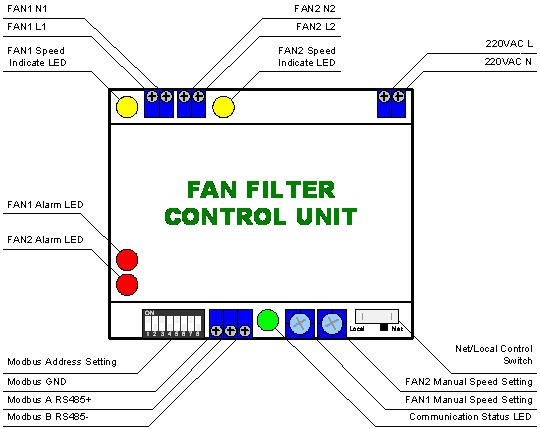

Indicators |

Power

Supply |

Red |

|

FAN

Normal |

Green

(x2) |

|

FAN

Speed |

Yellow

(x2) |

|

FAN

Error (Idle, Overcurrent) |

Red

(x2) |

|

Modbus

Communication |

Green |

|

Switch |

Remote/Local Select |

ON/OFF

Switch |

|

Modbus

Address Setting |

Red DIP8

Switch |

|

Potentiometer |

Velocity

Adjustment of FAN Speed |

Blue

(x2) |

|

Alarm

Output |

Dry

contact. Sound option available |

|

Certification |

CE, RoHS |

Connectors & Indicators

WARNING:

Dangerous voltages are present on the circuit

board when connected to the power line. Power must be removed

before making any connections oradjustments to avoid electrical

shock or damage to the unit.

Other Applications

Special Offer

Unit Price*:

Euro 19.90

* Minimum Order Amount May Applied

Three-Phase AC

Variable Speed Drive

|

Model:

FCU121 |

☺ |

Modbus RTU |

☺ |

50/60Hz |

☺ |

110-480VAC |

☺ |

1/2-2HP |

Features

-

115V, 230V, 380-460V ratings

available

-

Single Phase & Three inputs/

Three-phase output

-

Integrated Modbus RTU serial

communications

-

Motor current and RPM LED

Front Panel readout

-

150% overload for 60 secs.

(175% for 2 secs.)

-

Variable or constant torque

-

Unique programmable boost to

achieve intelligent starting

-

Keypad control

-

Simple operations with

powerful easy to use features

-

Fast Setup, Pre-programmed

factory defaults, only 14 parameters

-

Integrated RFI Filter option

-

Small mechanical footprint

-

Rugged industrial 50 DegC

ambient rating

-

Simple mechanical & electrical

installation

Overview

Fan Filter Control Unit

(FCU121) is a

commercially competitive also heavily featured VFD available

in the market, which combines functionality with robustness,

reliability and easy to use programmability. The product is

dedicated to Three Phase output applications where total

cost are very competitive, including:

Complete Product features,

specifications, and electrical data, please contact us.

Order Information

| Order Code |

Description |

Unit Price (Euro)* |

| FCU121-S-05 |

VSD 200-240V- 1 Phase

input - 3 Phase 230V Output, 0.5HP (0.37kW), IP 20

|

69.90 |

| FCU121-T-05 |

VSD 200-240V- 3 Phase

input - 3 Phase 230V Output, 0.5HP (0.37kW), IP 20

|

69.90 |

| FCU121-S-10 |

VSD 200-240V- 1 Phase

input - 3 Phase 230V Output, 1.0HP (0.75kW), IP 20

|

119.90 |

| FCU121-T-10 |

VSD 200-240V- 3 Phase

input - 3 Phase 230V Output, 1.0HP (0.75kW), IP 20

|

119.90 |

| FCU121-S-20 |

VSD 200-240V- 1 Phase

input - 3 Phase 230V Output, 2.0HP (1.5kW), IP 20 |

149.90 |

| FCU121-T-20 |

VSD 200-240V- 3 Phase

input - 3 Phase 230V Output, 2.0HP (1.5kW), IP 20 |

149.90 |

* Minimum Order Amount

may applied

DC Motor Control

LonWorks Control System

|

Model: 32081 |

☺ |

FT10 |

☺ |

220VAC |

Features

-

OEM best choice for FFU

manufactures

-

LonWorks core module embedded

with Free Topology Transceiver

-

Easily programmed to interface

different DC Motors with RS485 port

-

Acquires and reports two alarm

outputs from FFU with LED indicators as united interface

-

AC power source from FFU

itself

-

Simple mechanical & electrical

installation

Overview

Control Unit

(32081) is a dedicated

designed circuit board with LonWorks and RS485 interfaces

for DC motors like from EBM. It is a very fast and cost effective way

to turn your FFU into native LonWorks device. Complete Product features,

specifications, electrical data and sample source code, please contact us.

Another approach to integrate

with other LonWorks systems, is to consider our

LonWorks

Serial Programmable Gateway, which could act as gateway of

up to 64 DC motors to LonWorks system. STIT has worked with

a few wellknown FFU manufactures successfully delivering

such applications:

Order Information

| Order Code |

Description |

Unit Price (Euro)* |

| 32022-B-FFCU |

LonWorks Serial

Programmable Gateway - FT10 - 24VDC - Preprogrammed for

EBM DC Motor - DIN |

169.90 |

| 32081-EBM |

EBM DC Motor LonWorks

Interface Circuit Board |

79.90 |

* Minimum Order Amount

may applied

Other

Related Products

FFU Alarm Circuit Board (Model: FCU908) - A OEM module

with Modbus interface for networking and 2 alarms realtime

reporting. Designed for a well known FFU manufacture. Very

compact, excellent performance and cost effective. Contact us

for details, or any ideas you may have for your equipments.

|